The uprising at the world’s largest iPhone factory has caused problems for the company. Now they are looking towards India.

Several years of severe coronary artery strictures. insomnia and protests In the iPhone factory in Zhengzhou, China.

The group has been created Big problems For Apple Foxconn supplier. Therefore, Apple is now abandoning its plans to reduce its dependence on China, he writes The Wall Street Journal.

One in four phones by 2025

India in particular is winning from this.

Earlier this fall, it became known that Apple had asked suppliers to move production of AirPods and Beats headphones from China to India.

In the next few years, production in India will be scaled up: a recent analysis carried out by Reuters news agency It predicts that one in four iPhones will be manufactured in India by 2025.

To manage this, Foxconn, Apple’s manufacturing partner, will hire 53,000 people there over the next two years.

Huge production deficit

Demonstrations broke out at the factory in Zhengzhou in November. Many of the more than 200,000 workers believed that the factory had too strict coronary artery restrictions. In addition, they believe they were not paid as promised.

The protests at the factory in Zhengzhou have already cost Apple dearly.

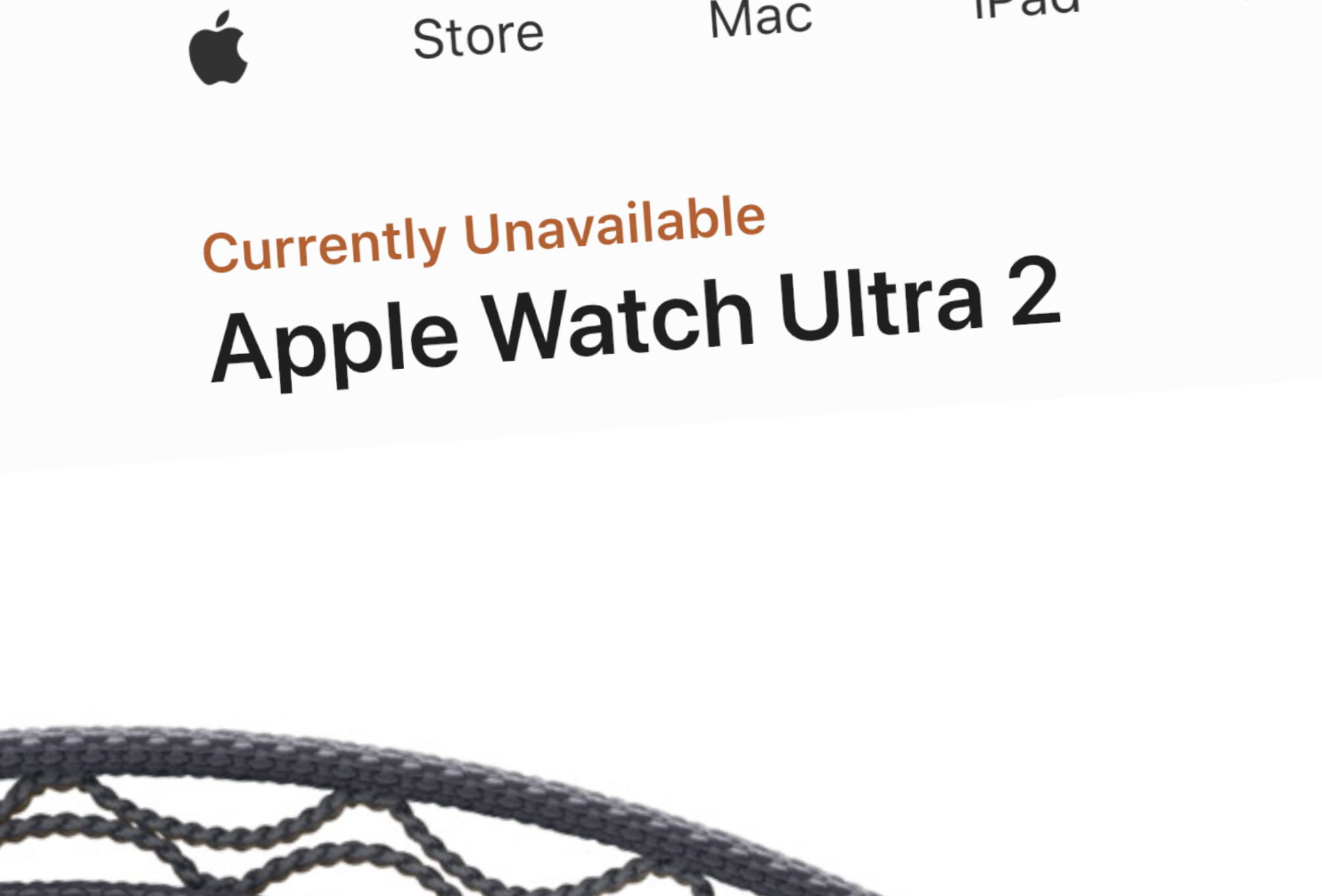

Two weeks ago, the tech giant announced that there would be a delay in the delivery of the new iPhone 14 industry today Apple is heading for a production shortfall of six million iPhones this year.

That’s one reason the tech giant has deemed it safe to bundle much of its business in one place, according to analysts and people in the Apple system the Wall Street Journal spoke to. Many companies are also lining up to produce more for Apple, the paper writes.

China is still the largest

But according to Reuters In the analysis, there is also no country that will be able to take over from China for a long time yet.

– The Chinese supply chain will not disappear overnight, Associate Professor Eli Friedman at Cornell University tells Reuters.

Vietnam and India are not China. They cannot produce at the same volume and quality and with the same reliable infrastructure.

China is the last major economy in the world that still has its strategy in place to suppress the virus outbreak when it happens. Rapid lockdowns, mass testing and long-term quarantines are still frequently used, despite the fact that they cause problems for business and international supply chains.

The workers flee

The plan now is to isolate the factory workers’ contact with the outside world to a minimum, he writes The Wall Street Journal. Factory workers should mainly stay in the production area.

But many employees believe that the salary they receive does not make up for the crackdown. So some choose to run away, and the factory will now be short of several thousand workers. So Foxconn is offering money to get workers back to work.

China’s strict no-contagion policy has led to protests in many places in China recently. Demonstrations of the scale seen in recent weeks are highly unusual in China.

“Web specialist. Lifelong zombie maven. Coffee ninja. Hipster-friendly analyst.”