Many companies in the food and beverage industry are constantly reaping the benefits of artificial intelligence (AI). It is expected to exceed the market value $35 billion by 2028And there will be big profits to be made – from farm to fork.

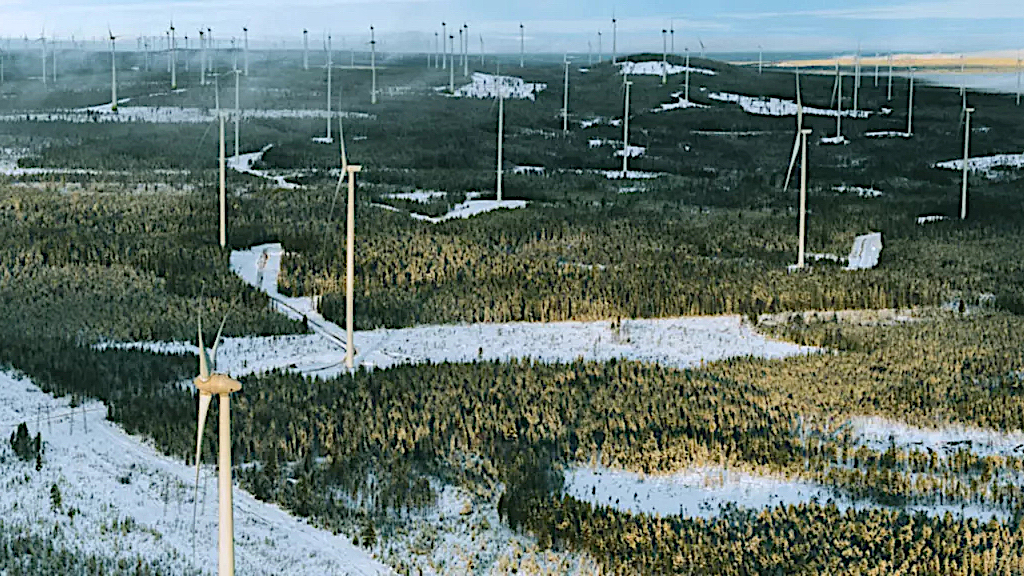

Sigurd Island. Photo: Infor Norway

AI can bring countless business benefits to the food industry and, most importantly, ensure you stay one step ahead. It simply requires adapting to the specific needs of the company, appropriate data collection and processing, as well as proper training of AI models.

Overall, AI (particularly machine learning) has the potential to improve all areas of food production. With its ability to calculate countless data values and parameters, as well as devise various “what-if” scenarios, machine learning can improve efficiency and provide accurate and timely recommendations for all possible aspects of the supply chain.

Here are some examples:

- Better optimization of irrigation, fertilizer, feed and production: Machine learning can provide more knowledge and analysis. It can be an analysis of which fields need irrigation and when or when to apply fertilizers in relation to weather forecasts based on data from previous years’ crops, quantity and quality of crops, as well as wind and weather. In the field of aquaculture, the leading company in the field of animal nutrition has Neutrico, achieved additional production cycles with healthier shrimp, while using 30 percent less feed. Specifically, the company uses acoustic sensors in aquaculture to listen to shrimp and understand when they are hungry. Machine learning then determines when and how much to feed the shrimp, reducing feed transfer and shortening the shrimp production cycle.

- Faster product recommendations for customers: Global company Zeelandia Group, which develops and produces ingredients for bakeries, has implemented a machine learning-based model that recommends products to customers. The model addresses the challenges of high costs and shortages of available ingredients and can recommend alternative products to bakery customers. Product recommendations are 83 percent faster to set up, reducing time from 30 to 5 minutes. This provides a better customer experience and increased income per transaction.

- Better quality and less waste in production: Dutch goat cheese producer Amalthea is using machine learning to make cheese quality more predictable, maximize yield, build customer loyalty and increase sustainability. Previously, Amalthea could only manually analyze milk volume on a weekly basis, but machine learning provides insight into production throughput and reasons for yield changes instantly. By identifying weaknesses and improving processes at the same time, the total Amalthea waste resulting from production has been reduced. For every 1 percent increase in profits, Amalthea expects to save approximately 500 thousand euros.

These examples are largely based on historical data and real-time data. But how does AI deal with highly unpredictable conditions, such as weather and wind? according to Food and Agriculture Organization of the United Nations (FAO) All participants in the food industry supply chain must be stronger and reduce the use of water, energy and other resources. Here too, AI can make a positive contribution. Weather is currently the most difficult factor to predict in agriculture. Drought in the cold north and floods in the south are a reality. Although data patterns are unpredictable, machine learning helps better understand business risks related to weather changes and what precautions should be taken to secure the harvest.

Sigurd Island

Senior Account Manager at Infor Norway

“Web specialist. Lifelong zombie maven. Coffee ninja. Hipster-friendly analyst.”